Capabilities

Materials

Most of our work is in aluminum and stainless steel, but we can handle most common and some uncommon engineering materials.

6061-T6 Aluminum

303, 304, and 316 Stainless Steel

1018 and A36 Mild Steel

UHMW, Acetal, Nylon, PTFE, PEEK

Titanium, Inconel, and Hardened Alloys

Quantities

Quantities of 1 piece to 1,000+.

Turning size limit is about 6" diameter.

Size limit for milled parts is about 16" x 28", although we can also machine long parts if they are less than about 12" width.

Heat Treat

We can provide through hardening and case hardening of steel components. We can also provide finish machining on hardened components.

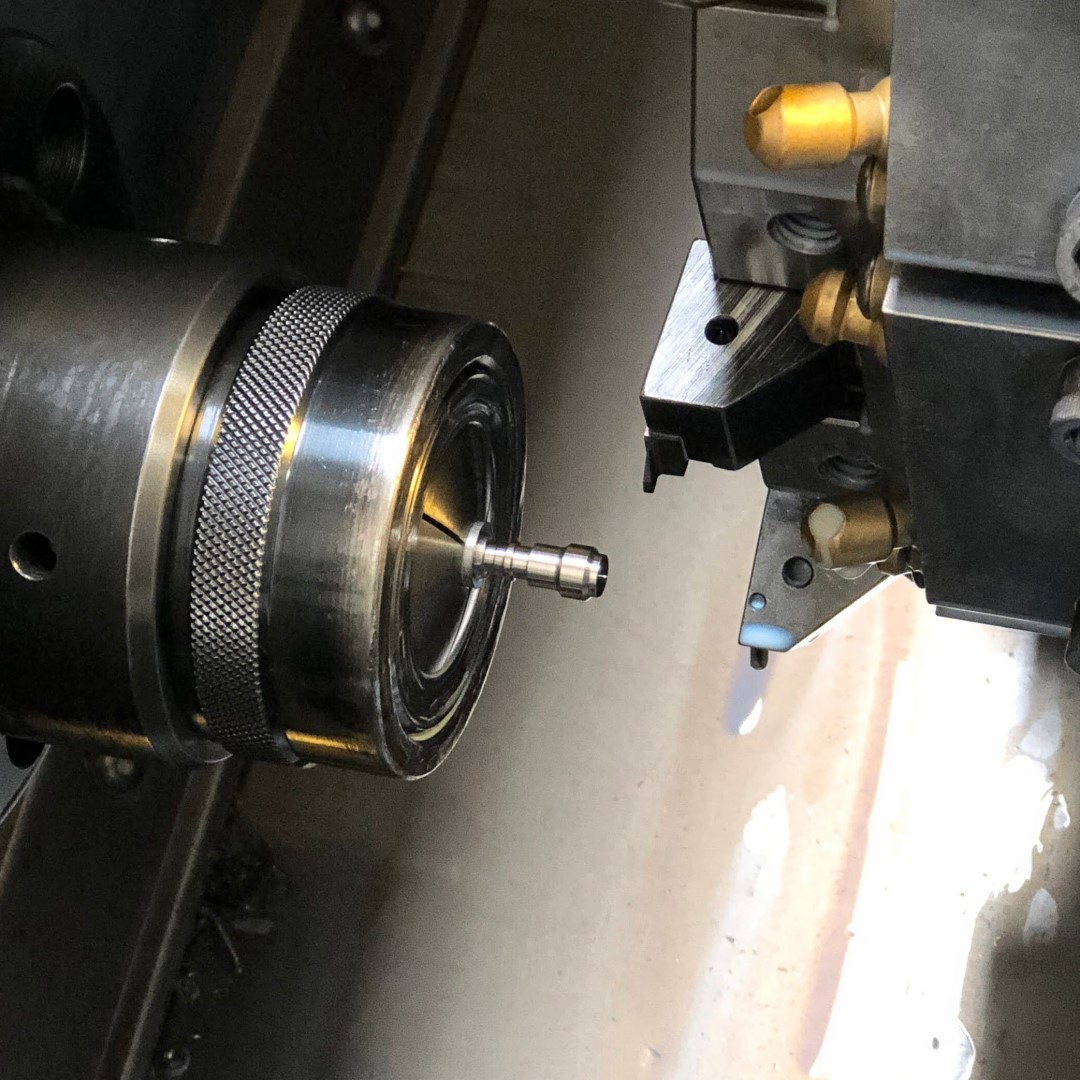

Hard Turning

We use CBN inserts to finish turn hardened components up to Rc60. Hard turning provides an excellent surface finish and in many cases can replace grinding operations at a lower cost.

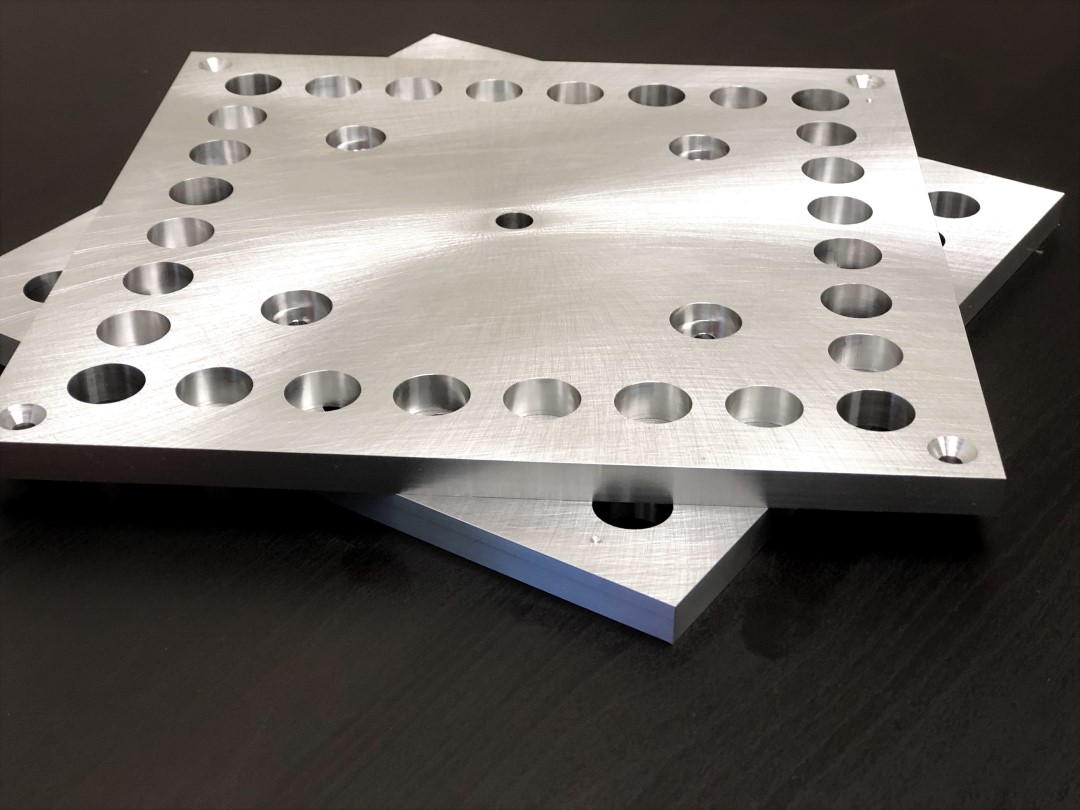

Blanchard Grinding

Blanchard grinding is our go-to method to face large plates with excellent flatness and parallelism. Blanchard grinding leaves a unique swirl pattern.

Finishing

Our location on the outskirts of Los Angeles places us within the service area of some of the best finishing shops in the country. We can offer 1-2 day turn-around on anodizing, chem-film, passivation, black oxide, and zinc chromate. In addition, we offer painting, hard anodize, and laser marking.